How to successfully set up a coal briquetting (briquetting) plant?

- 2024-07-19 16:49:00

- admin Original

- 79

The briquetting system we design is a multi-purpose one, it can be of various materials. These materials include but are not limited to coal, charcoal, coke and mineral powders or dust.

We build successful briquette production projects

Below are some of the briquetting projects designed and built for our clients. Check out the site photos to learn more about starting a briquetting business.

1 Ton per Hour Coal Cinder Briquetting Project in Malaysia

8 Tons per Hour Mineral Powder Briquetting Plant

Our complete briquetting production line is customized to the specifics of our clients’ raw materials and production capabilities, thus ensuring that the briquetting plant provides satisfactory service to our customers. In addition, we generously provide technical support to our esteemed customers.

Coke/briquette manufacturing process

Here are the things you should know before setting up your own coal briquetting plant or starting a briquette business.

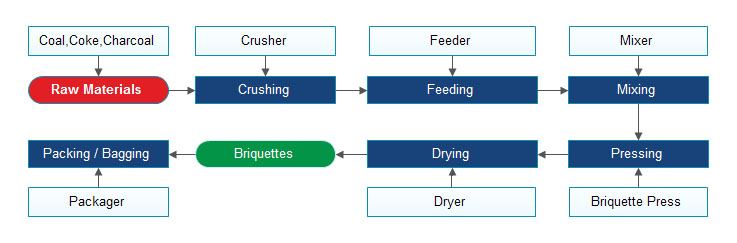

1. Flow chart of briquetting process:

Raw materials > Crushing > Feeding > Mixing > Pressing > Drying > Briquetting

2. Common raw materials for coal briquette production line:

The following are materials that can be used in coal briquette plant processing:

- Coal dust

- Charcoal dust

- Coke dust

- Carbon black

- Mineral powder (such as manganese ore powder, nickel powder, silicon carbide)

- Lime powder

- Other powdered materials

3. Main equipment for coal briquetting production:

The following are commonly used equipment in coal briquetting plant design.

Crusher machine

Compound crusher, widely used for crushing raw materials and clinker in cement plants. It can also be used for crushing medium hardness materials such as dolomite, coal, flint, lead-zinc ore, serpentine, blast furnace slag, coal gangue, shale, phosphate rock, etc. It is especially suitable for the manufacture of artificial sand such as hard limestone, dolomite, granite, basalt, or the processing of road pavement stone.

Characteristics of crusher

- Large crushing ratio, which can be adjusted arbitrarily.

- No screen, no block.

- With elastic adjustment mechanism, hard impurities can be automatically discharged without causing damage to the equipment.

- Horizontal bearings, long service life, can destroy high-temperature materials (such as cement clinker).

- The structure of the machine rotor is unique. The rotor will hardly wear out when working.

- The rear chamber is equipped with a screw or hydraulic opening mechanism, which allows easy replacement of fragile parts without opening the main machine.

Mixing equipment

Spiral Mixer

The spiral mixer consists of a U-shaped tank, a screw and a drive component. The outer screw moves the raw materials from both sides to the central space, and the inner screw moves the raw materials from the central space to both sides to achieve efficient convection mixing. The spiral mixer can mix a variety of materials, especially powders and granules in large production lines.

In the production process, the binder mixer and the liquid mixer are arranged in series

- The liquid mixer first mixes the binder and water into a proper proportion, and then uses some measurable equipment to provide the binder mixer with a sufficient amount of materials at the right time. >

- The binder mixer further mixes the process by mixing ground coal powder or charcoal powder (charcoal powder), etc. with water and binder, etc. Then, it automatically discharges the mixed material without human help.

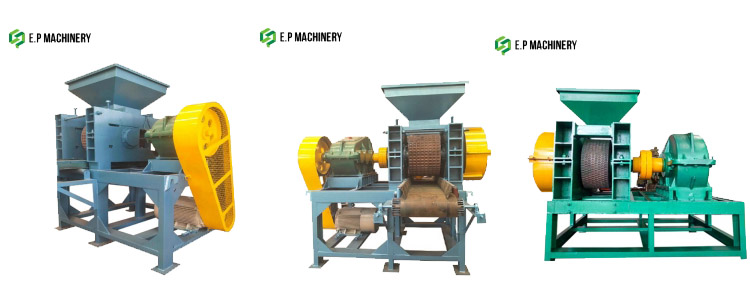

Coal Briquetting Machine

Coal Briquetting Machine

All our briquette machines are here. We can help you choose the right briquetting machine according to your budget and raw materials.

Our briquetting systems are designed to be flexible and can handle a variety of materials such as coal, charcoal, coke and mineral dust.

The production line is customized according to customer needs to ensure efficient and satisfactory output.

We provide comprehensive technical support to help you run your briquetting business smoothly.

Final Briquettes

After being pressed by the briquetting machine, the final briquettes can be formed and carved into any desired shape.

Tell us the details of your raw materials and production capacity, and our professional team can customize the briquetting production line for you, so as to ensure that we can provide you with satisfactory service and technical support

| Contacts : | Chris Wang |

|---|---|

| Phone : | +8613633713237 |

| Email : | chris@ep-machine.com |

| Wechat : | +8613633713237 |

| Whatsapp : | +8613633713237 |

| SNS : |

|